HVAC V-Belts

When it comes to repairing a belt-driven HVAC unit, throwing on the v-belt and walking away is not the solution. In most cases though, this is exactly what's done. People believe that v-belts do not need to be replaced until they have snapped completely. This is not true. V-belts will eventually start wearing out and stretching long before they snap, dropping the efficiency of your heating or air conditioning unit.

Before you sign a contract for a preventive maintenance program, make sure your contractor:

- Checks the condition of sheaves for worn or damaged grooves

- Cleans the pulleys

- Aligns the sheave faces

- Tensions the belt properly

- Check the drive's tension

Above is a photo of a bad v-belt. Belts are supposed to be tensioned properly so that they don't touch. Also, take a look at the worn-out condition of the belt. It needs to be replaced. Seeing this on a unit can tell a professional and experienced contractor a few things: cooling stages will freeze the unit, air flow is restricted, high chances of water leaks, and possible compressor damage. If caught early, these can prevent costly repairs. Whether it's for exhaust fans, air handlers, furnaces, or air conditioners, a properly installed v-belt can help your unit run at its full life and efficiency.

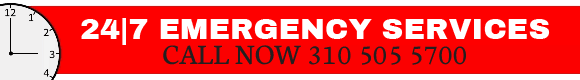

Have a problem with your air conditioning and its drop in efficiency?

Have some free time? Visit our YouTube page for videos on the services we provide, blog, or social media (listed below). Thank you!

Most Commonly Used Belts:

Type "A" V Belts

- Manufacturing range: 12" to 240"

- Inside length + 2 = outside length

- Top width: 1/2"

- Depth: 5/16"

Bad Examples:

Good Example: